________________

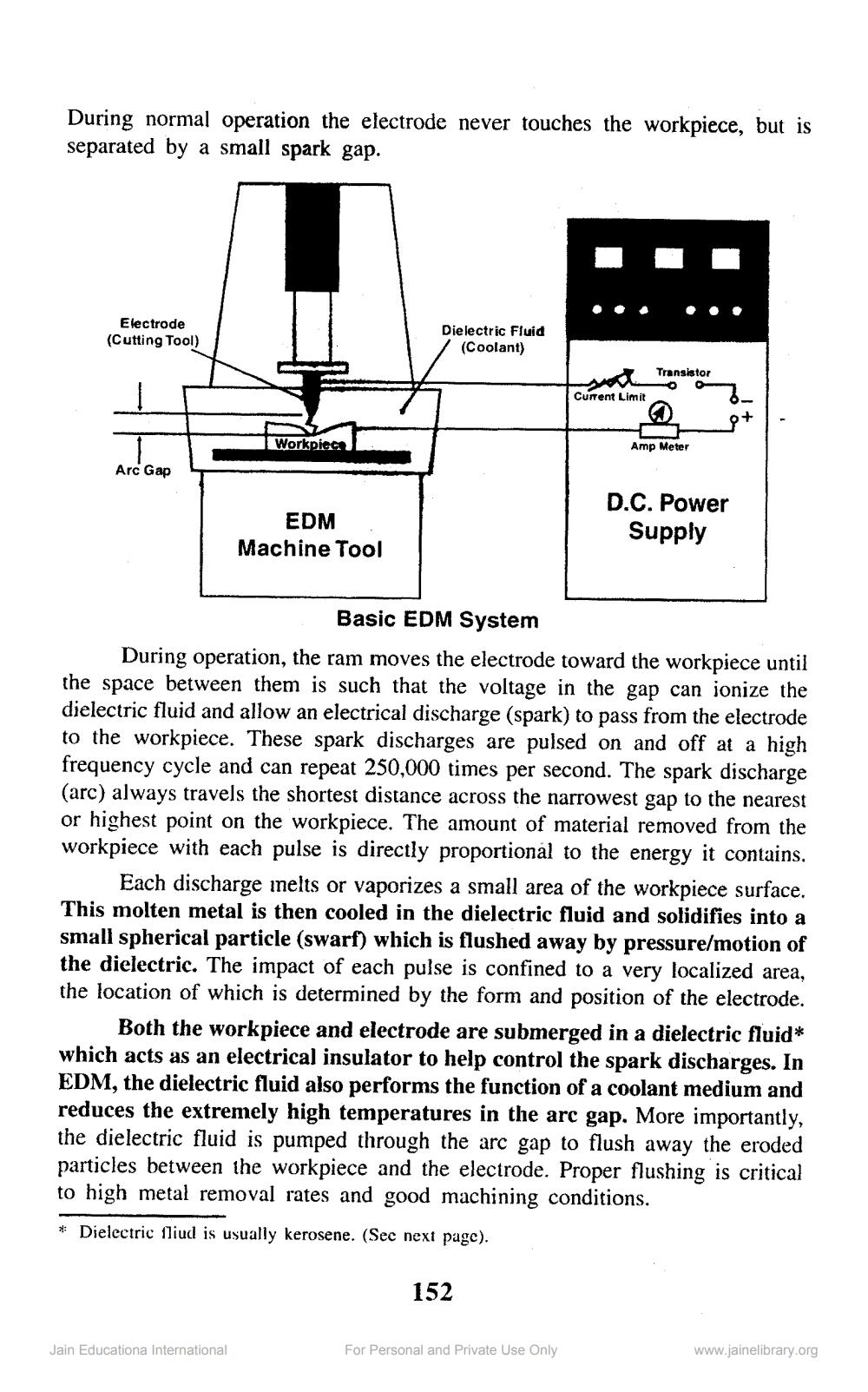

During normal operation the electrode never touches the workpiece, but is separated by a small spark gap.

Electrode (Cutting Tool)

Dielectric Fluid

(Coolant)

Transistor

O

Current Limit

Workpiecel

Amp Meter

Arc Gap

EDM Machine Tool

D.C. Power

Supply

Basic EDM System

During operation, the ram moves the electrode toward the workpiece until the space between them is such that the voltage in the gap can ionize the dielectric fluid and allow an electrical discharge (spark) to pass from the electrode to the workpiece. These spark discharges are pulsed on and off at a high frequency cycle and can repeat 250,000 times per second. The spark discharge (arc) always travels the shortest distance across the narrowest gap to the nearest or highest point on the workpiece. The amount of material removed from the workpiece with each pulse is directly proportional to the energy it contains.

Each discharge inelts or vaporizes a small area of the workpiece surface. This molten metal is then cooled in the dielectric fluid and solidifies into a small spherical particle (swarf) which is flushed away by pressure/motion of the dielectric. The impact of each pulse is confined to a very localized area, the location of which is determined by the form and position of the electrode.

Both the workpiece and electrode are submerged in a dielectric fluid* which acts as an electrical insulator to help control the spark discharges. In EDM, the dielectric fluid also performs the function of a coolant medium and reduces the extremely high temperatures in the arc gap. More importantly, the dielectric fluid is pumped through the arc gap to flush away the eroded particles between the workpiece and the electrode. Proper flushing is critical to high metal removal rates and good machining conditions.

* Dielectric fliud is usually kerosene. (Sec next page).

152

Jain Educationa International

For Personal and Private Use Only

www.jainelibrary.org